Universal Robots (UR) produces world-leading collaborative robots (cobots). Keeping a strong position in the robotics industry requires high-quality production and well-managed resources. That is why UR chose a solution by ROEQ and Mobile Industrial Robots (MiR) to automate the repetitive logistics in its warehouse and production.

ROEQ and MiR: an effective and user-friendly experience

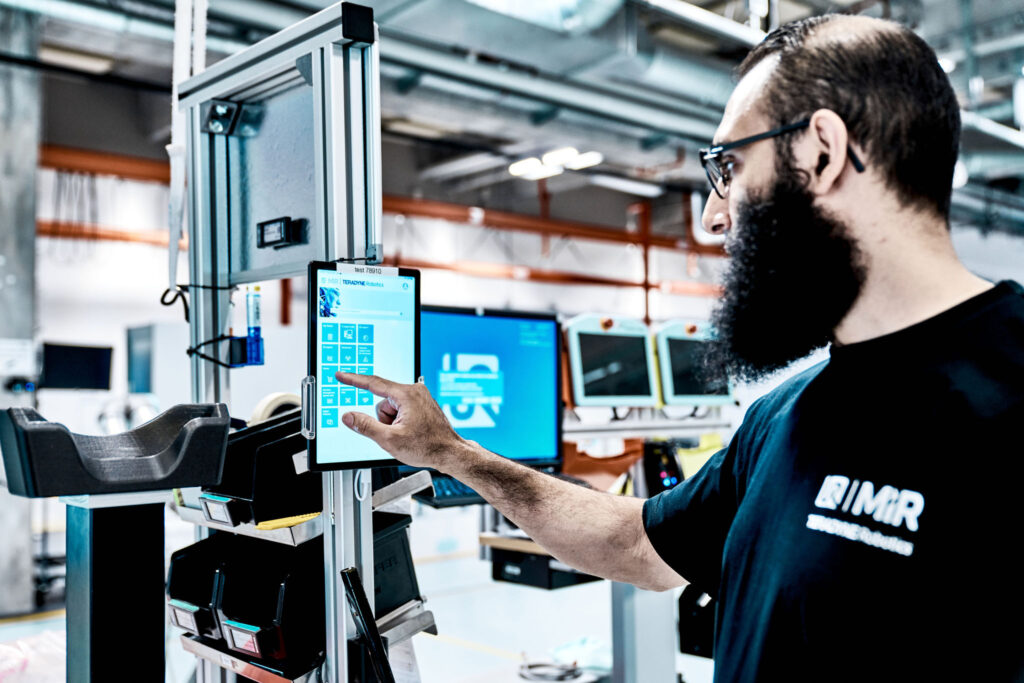

UR’s solution includes a ROEQ TML200 lifter on top of a MiR250 autonomous mobile robot (AMR). The ROEQ lifter enables the AMR to lift, move, and drop off goods between UR’s warehouse and production as well as production and shipping area. Most importantly, UR production workers have an easy time using the solution, as they simply order the AMR’s trips and tasks via a few clicks on an iPad.

More time, more safety, less back pain

Since implementing the solution, UR has enjoyed a five-hour reduction in forklift operations – per day! This has improved workplace safety: forklift operators must constantly scan their surroundings to avoid collisions with co-workers, while MiR and ROEQ’s solution stops automatically in case someone steps in front of it. Additionally, UR’s workers have more time for doing actual, value-adding work.

Another highly-valued benefit by UR workers is the improved ergonomics that come with the solution. The ROEQ TML200 lifts and delivers product boxes to ROEQ pallet racks with special gaps for the workers’ feet. This allow workers to stand flush against the racks while loading products into the boxes, which leverages biomechanics to maximize strength and minimize the back strain that comes with excessive hunching.

Customize creatively with ROEQ carts

UR’s solution also includes a large fleet of ROEQ carts that can both be transported with ROEQ top modules and via manual handling. The carts’ mounting holes moreover allow companies to install their own custom storage equipment on top of the carts. UR has taken advantage of this possibility by installing their own shelves specifically designed for UR’s materials and way of working.

A useful solution that you can rely on

UR finds the ROEQ-and-MiR solution useful, and it is easy to see why. With significantly reduced process times in production, UR has a reliable solution whose value is evident to the entire organization. At ROEQ, we find this to be a good example of why companies should consider automating their internal logistics: the benefits abound and are easy to notice.